Parts.

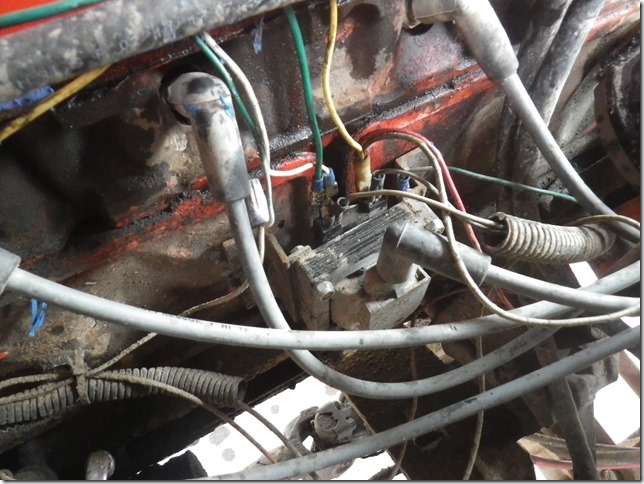

I ordered a new Distributer and wires on Friday.

The plug wires arrived on Sunday the Distributer won’t get here until between the 6/28 and 7/3.

Going to Bob’s.

Bob has the chip from the Engine Control Module for his old six cylinder engine.

I decided that it would be a good test, to swap the chips and see if it makes any difference so I drove over to Bob’s .

Peeps.

When I got to Bob’s, he was working on roosts for his chickens.

We sat around for a while in the chicken run and watched the peeps playing in the tall grass.

Bob dug up some worms and gave them to the peeps.

It was fun to watch them. One of the chicks would get a worm…

and the rest would chase it around trying to steal it.

After a playing chase the worm for a while, I guess they worked up an apatite because a bunch of them attacked the feeder.

Fresh Fruit.

Fresh Fruit.

After a while we wandered around Bob’s place picking and eating plums and some raspberries.

Chip Swap.

Okay it is time to swap out the chip in the ECM. It only took a few minutes to remove the ECM and swap the chips.

Test Drive.

Once that was done I took the van for a test drive.

I pulled out of Bob’s place and punched it. The van took off with out any hesitation.

I had to drive the rest of the way to town at 35 mph (The speed limit). Once I got on River Road I drove east through some small communities.

Once I got past the last town and on a stretch of open road near the Korbel Winery I punched it.

The van took off like I thought it should. I was very happy as I thought we had finally found the problem with the van.

I pulled off the road so I could turn around. I had to wait for a string of cars to go by before I could take off.

There was a clear spot between cars so I punched it to get on the road. The engine almost quit. It stuttered and missed and jumped until I backed off the throttle so it wouldn’t quit.

I shifted into second and eased the throttle on. The engine stuttered and missed but slowly accelerated.

I made it without getting run over but it was a close thing.

Back at Bob’s

We discussed the problem but didn’t come up with anymore Ideas.

I will just have to wait until after I change the distributer and see if that does anything good.

Heading Home.

After a bit I headed for home. The engine seemed to run pretty good until I had to take a detour around Forestville.

By the time I got back to Guerneville Road, the van was running real rough.

When I got to the stop sign at Guerneville Road, the van had a hard time getting going again.

Eventually I was able to coax it onto the highway but it wouldn’t accelerate. It was even backfiring.

I had to pull off the road to keep from getting run over.

Once I stopped, I raced the engine a couple times and it seemed to clear up.

I took off carefully and was able to get up to highway speed.

It acted up a little occasionally, especially after siting at a long stop light but I got home ok.

Going to the Cabin.

I am planning on going to the cabin tomorrow (Wednesday) but I don’t think I am going to trust the van to the go up there.

I guess I’ll take the jeep.

I’ll worry about the van when I get back after the fourth of July.